Gas Analyzer

Green Industry designs and manufactures comprehensive gas and Continuous Emissions Monitoring System (CEMS) analyzer packages in collaboration with leading manufacturers to provide accurate, reliable, and advanced solutions for industrial and environmental applications. These packages are essential for monitoring and controlling gas emissions, ensuring compliance with regulatory standards, and optimizing industrial processes. Here is a detailed description of the gas and CEMS analyzer package:

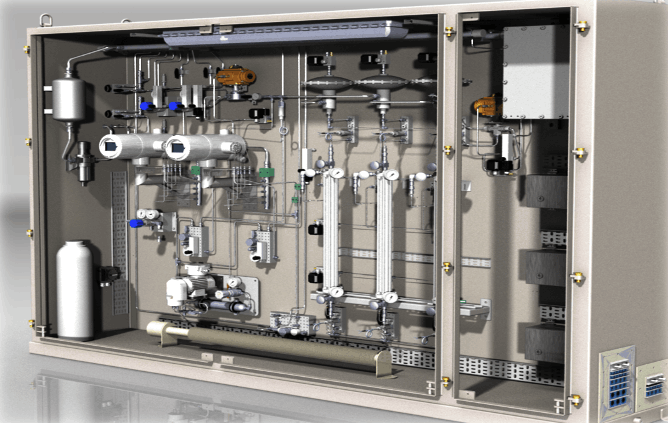

Components of the Gas and CEMS Analyzer Package

1. Primary Gas Analyzers:

– Multi-Gas Analyzers: Capable of detecting and measuring multiple gases such as CO, CO2, NOx, SO2, O2, and VOCs.

– Infrared (IR) Gas Analyzers: Use infrared absorption technology to measure specific gases like CO2, CH4, and hydrocarbons.

– Electrochemical Gas Analyzers: Detect gases like O2, CO, NO2, and H2S using electrochemical sensors.

– Photoionization Detectors (PID): Measure volatile organic compounds (VOCs) using UV light to ionize gases.

– Thermal Conductivity Analyzers: Measure the thermal conductivity of gas mixtures to determine specific gas concentrations.

2. Sample Conditioning System:

– Probes and Filters: Collect and filter gas samples to remove particulates and moisture.

– Sample Lines: Heated lines to transport gas samples to the analyzers without condensation.

– Pumps and Flow Controllers: Ensure consistent sample flow and pressure to the analyzers.

3. Data Acquisition and Control System:

– Data Logger: Collects and stores data from all analyzers for historical analysis and trend monitoring.

– Control Unit: Integrates with the data logger to provide real-time control, alarms, and data visualization.

4. Communication and Networking:

– Protocols: Supports industry-standard communication protocols like Modbus, Profibus, and Ethernet for seamless integration with SCADA systems and other control networks.

– Remote Monitoring: Capabilities for remote access and control, allowing operators to monitor and adjust parameters from a distance.

5. Calibration and Maintenance System:

– Calibration Gas Cylinders: Provide known gas concentrations for regular calibration of analyzers.

– Automated Calibration Routines: Ensure continuous accuracy and reliability of measurements.

– Self-Diagnostics: Identify potential issues and alert operators before they lead to system failures.

6. Power Supply and Backup:

– Primary Power Supply: Reliable power source to ensure continuous operation of all components.

– Uninterruptible Power Supply (UPS): Provides backup power to prevent data loss and downtime during power outages.

7. Housing and Mounting:

– Enclosures: Robust, weather-resistant enclosures protect the components from environmental factors like dust, moisture, and temperature extremes.

– Mounting Kits: Versatile mounting options for wall, panel, or skid installations, suitable for various industrial settings.

Key Features

1. High Accuracy and Sensitivity:

– Advanced sensor technologies and precision instruments ensure accurate and reliable measurements even at low concentrations.

– Calibration and compensation features maintain the integrity of data over time.

2. Integrated System:

– All components are seamlessly integrated, providing a comprehensive solution for gas analysis and emissions monitoring.

– Modular design allows for easy expansion and customization to meet specific application needs.

3. User-Friendly Interface:

– Intuitive touchscreens and graphical displays for easy operation, configuration, and data interpretation.

– Configurable alarms and alerts notify operators of critical parameter deviations.

4. Automated Functions:

– Automated calibration and cleaning routines reduce maintenance requirements and enhance system longevity.

– Self-diagnostic features identify potential issues before they lead to system failures.

5. Compliance and Standards:

– Instruments and components meet international standards (e.g., EPA, ISO, IEC) and certifications, ensuring compliance with regulatory requirements.

– Designed to adhere to industry-specific guidelines for emissions monitoring and process control.

Applications

1. Environmental Monitoring:

– Assessing air quality and monitoring emissions to ensure compliance with regulatory standards.

– Detecting and analyzing greenhouse gases and pollutants to mitigate environmental impact.

2. Industrial Process Control:

– Monitoring gas concentrations in manufacturing processes to ensure product quality and safety.

– Controlling combustion processes to optimize efficiency and reduce emissions.

3. Safety and Leak Detection:

– Continuous monitoring of hazardous gases to protect workers and prevent accidents.

– Detecting gas leaks in pipelines, storage tanks, and confined spaces.

4. Power Generation:

– Monitoring emissions from power plants to ensure compliance with environmental regulations.

– Optimizing combustion processes to enhance efficiency and reduce pollutant output.

5. Research and Development:

– Analyzing gas mixtures and reactions in scientific research and laboratory settings.

– Supporting innovation in new technologies and materials.

By designing and manufacturing gas and CEMS analyzer packages in collaboration with top-tier manufacturers, Green Industry ensures that their solutions meet the highest standards of quality, accuracy, and reliability, supporting a wide range of industrial and environmental applications.